EUROTECHNI IS PROUD TO PRESENT YOU ITS BRAND NEW WEBSITE!

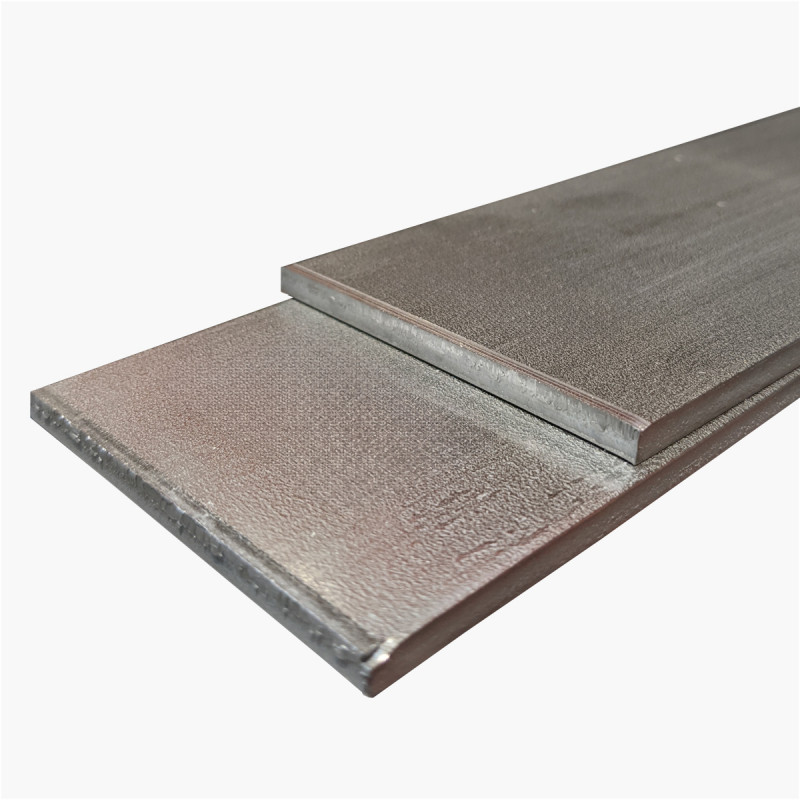

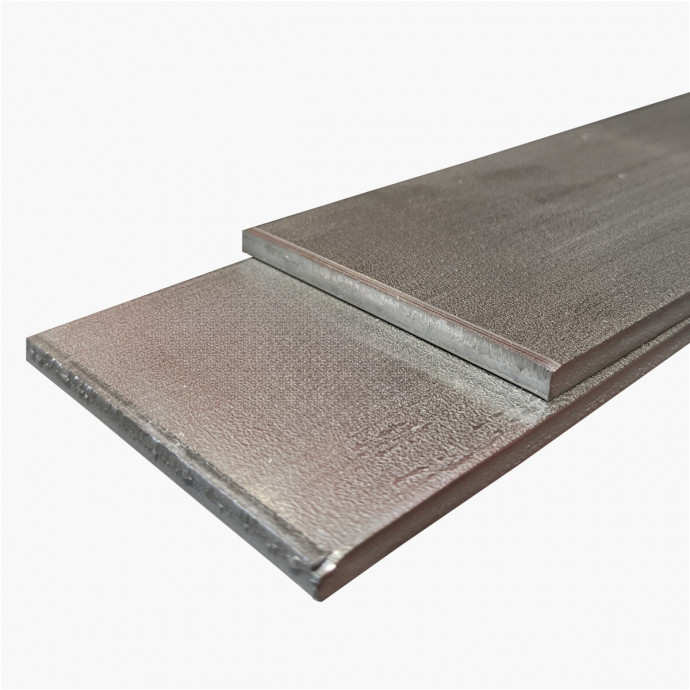

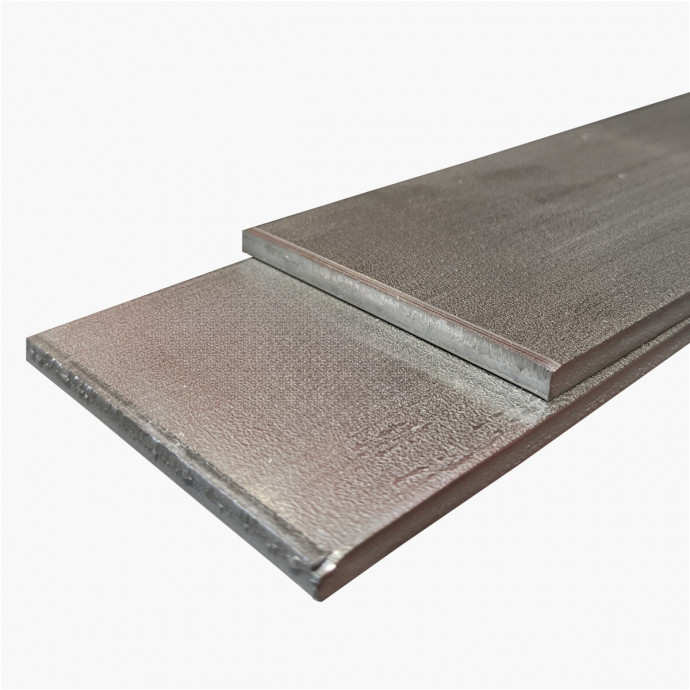

The X46Cr13, commonly known as Z40 in France, is the stainless steel most used in cutlery. Its carbon level of 0.46% allows it to obtain sufficient hardness for common use while obtaining correct results in terms of corrosion resistance.

With a good price/quality ratio it is the reference grade for any cutlery that starts working inox. Of relatively simple composition compared to other stainless steels such as N690, the heat treatment of X46Cr13 is simpler. The maintenance time at austenitization temperature is shorter than for stainless steels very strongly alloyed to chrome - 10 to 15 min is sufficient for a thickness of 3mm. As with all stainless steels, we strongly recommend the use of a tempering furnace at controlled temperature and the use of protective strip (paplot) stainless steel.

All stainless steels can be soaked in the air, but this does not mean that the room will cool to the ambient air. The cooling speed is extremely important to obtain the targeted hardness and guarantee the anti-corrosive properties. If you want to cool in the air, this can be done between aluminium plates or with pulsed air. The important thing is to pass the cooling speed by 10°C/second. This means that in less than two minutes the room must be at room temperature (under 70°C at heart)

You are looking for this shade in larger formats (plates, coils, dishes...) we have a very large stock available in many thicknesses. Do not hesitate to contact us via the contact form.