EUROTECHNI IS PROUD TO PRESENT YOU ITS BRAND NEW WEBSITE!

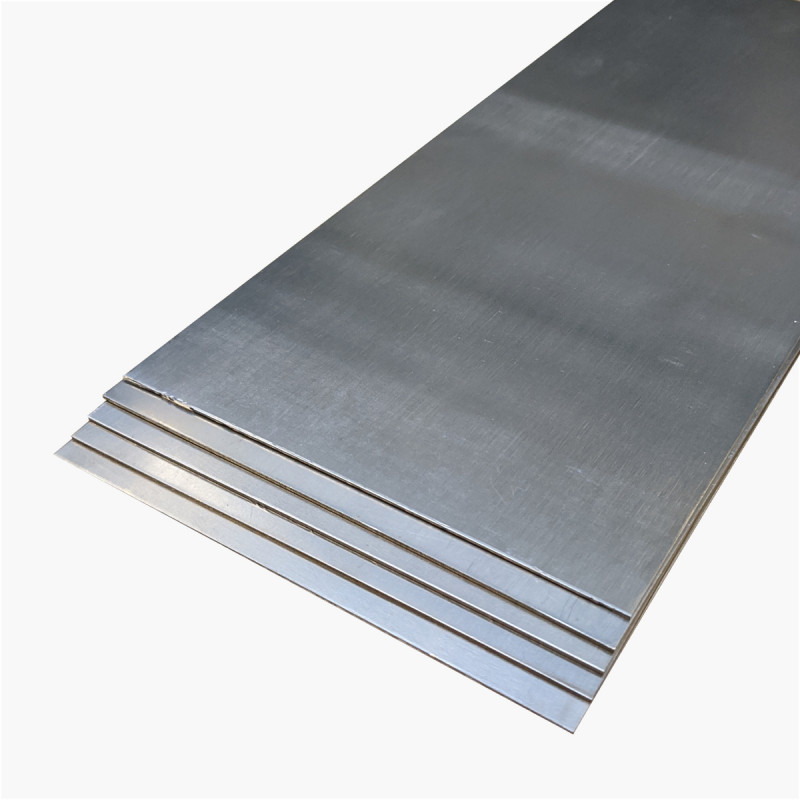

This range of Grade 5 TA6V titanium plates has been rectified on both sides for perfect calibration.

The surfaces are perfectly flat and the thicknesses uniform.

The rectification offers a clear advantage to the use since no machining operation is required to smooth and smooth the workpieces.

Simply choose from the available thicknesses the one that will be most suitable for the parts to be realized and devote itself to cutting and drilling operations without worrying about possible surface covers.

Titanium is now used in a wide range of applications, including, of course, the production of generally high-end knives.

Still widely used the biomedical sector, the energy, aerospace and military industries, titanium alloys have seduced in virtually all fields for, among other things, their anti-corrosive qualities, resistance, lightness, low thermal conductivity and insensitivity to magnetization.

Alloyed with aluminium/vanadium, Grade 5 TA6V titanium offers an excellent compromise between mechanical resistance, tenacity and ductility.

It is more difficult to work than inox, so it is better to use suitable tools, especially for drilling operations and tapping.

Of course, it can also be welded.

The qualities of this alloy are many and particularly interesting in the field of cutlery.

With a pleasant grey colour and a feather weight (4.43 g/cm3), this shade has an elasticity that allows the manufacture of liner-locks and frame-locks springs without resorting to the usual thermal treatments.

With available thicknesses of 1.5, 2.3, 4 and 5 mm, each of the elements of a closing knife can be shaped in this Grade 5 TA6V titanium, except the blade, of course.

Thanks to its extraordinary qualities, it is the Titan of cutlery and the most widespread of all alloy titaniums.

Liner-lock or frame-lock springs, platinums, ribs or mitres can be made entirely with this titanium grade for the manufacture of an ultra-light and ultra-resistant knife.

For assembly operations, titanium torx-printed screws of the same grade are available in our "Sellery" section of our online shop.

The Grade 5 TA6V titanium is originally a pleasant grey colour.

It can also be surface treated by anodizing to color it in the shade of its choice or as a support for a paint or varnish (based on teflon molybdenum) that will improve its friction properties.

A colouring can also be obtained manually by passing the part to the flame of a torch by avoiding reaching the temperature of 600° which could alter its mechanical characteristics.

With a little mastery, beautiful iridescent colours can be realized, ranging from pink to blue with more or less sustained tones.

The possibilities of colouring are multiple in accordance with the rules relating to the proper qualities of the Titanium.

Titanium accumulates so many mechanical qualities that it could be thought to have been derived from NASA research or directly from space.

Yet it is not.

Titanium ore was discovered in 1791 in the form of what was called "black sand" in a river of Cornwall.

From this sand, chemical experiments and treatments have produced an impure oxide of an unknown metal.

From 1795 to 1825, other discoveries and experiments made it possible to isolate this unknown metal and it was named "Titan", a nod to the Titans of Greek mythology, while completely ignoring its physico-chemical properties.

It took more than a hundred years to obtain 99% pure titanium in 1910 without any industrial development.

It was not until 1939 that industrial production and the exploitation of titanium really started.

It will have taken almost 150 years for the industry to find opportunities for this exceptional metal, whose alloys are now at the cutting edge of technology.