EUROTECHNI IS PROUD TO PRESENT YOU ITS BRAND NEW WEBSITE!

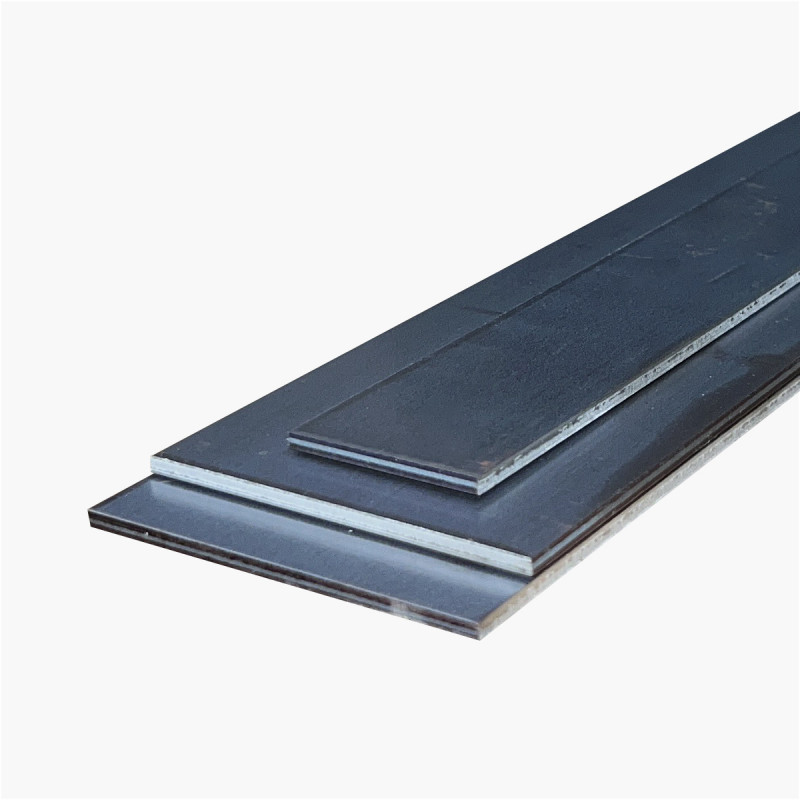

The Suminagashi VG10 sandwich steel consists of a central core VG10 covered on each side with 33 layers of non-dipping stainless steel that will give flexibility and ductility to the blades made in this material.

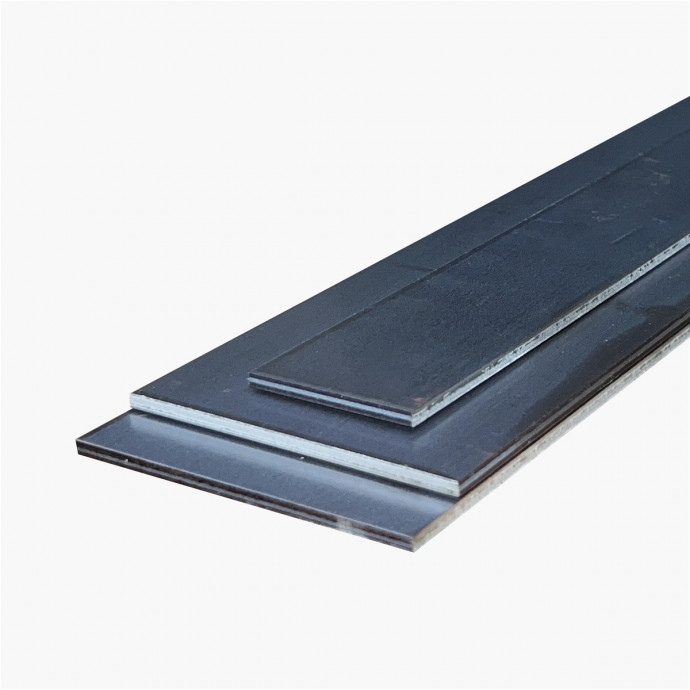

The stainless steel layers are composed of two different shades in the purest Japanese tradition of making swords and knives of chefs where the constant search for blades with exceptional edge goes hand in hand with remarkable aesthetic qualities.

Thus, the Suminagashi VG10 steel will be highly appreciated in the creation of chef and kitchen knives, but also for any other fixed blade knife.

After moulting, the blade shows the contrasts of the 66 layers of stainless steel on the VG10 stainless steel core, the exceptional edge of the blade.

To amplify contrasts, Japanese cutlery use a process of revelation similar to that of Damascus steel using acid or/and microboiler. This treatment highlights the layers of stainless steel to highlight a pattern made of sinuous or straight lines at the pace of motion (see details in the technical sheet). Others will prefer a clever hammering that will give a totally different but just as spectacular look to the blades.

Whatever the technique adopted, the Suminagashi VG10 steel guarantees blades of exceptional quality combined with a rare aesthetic, worthy of the Land of the Sun-Rising.